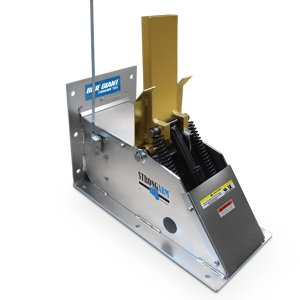

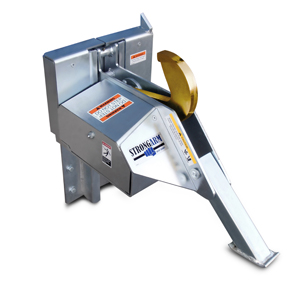

SVR303 StrongArm™

ANSI MH30.3 tested and approved, the StrongArm™ SVR303 is a low-profile, non-impact design with a rotating arm that seeks a trailer's ICC bar via a patented, switchless technology.

Once engaged, it uses 35,000lbs (15,909kgs) of restraining force to secure the truck to the dock. Dual-acting hydraulic cylinders prevent lock-up and release problems.

The Intelligent Positioning System (IPS) constantly communicates the location of the restraint arm via a network that enables the integrated lights communication system to accurately display safety conditions at the loading dock.

INNOVATIVE DESIGN AND OPERATION

- A profile that is one of the lowest in the industry (8”/ 203mm), significantly reducing the risk of impact damage

- Vertical restraining range from 8” to 26” (203mm to 660mm) above grade with minimum 4” (102mm) contact space required

- Horizontal restraining range up to 13” (330mm) from the face of the dock

- A high-visibility barrier-style restraint arm that uses passive engagement keep an ICC bar secured, resulting in less wear and tear and a lower lifetime cost of ownership

- An Intelligent Positioning System (IPS) that does not use mechanical switches and sensors to detect the ICC bar, resulting in more dependable performance

- PosiLock™ dual mechanical lock system that guards against accidental trailer separation and ensures safe, reliable performance during all stages of the engagement cycle

- Submersible: NEMA6 IPS sensor and double-acting hydraulic cylinders keep the unit operating safely and efficiently during wet or flooded conditions

- Restraint arm dislodges or breaks apart obstacles that prevent it from properly parking

INTELLIGENT TOUCH CONTROLS

- The Blue Genius™ Gold Series II Touch Control Panel features include an LCD menu screen, function buttons and a flat surface keypad with unique touch sensors

- Interior and exterior LED lights keep drivers and warehouse personnel advised of safety conditions

- Audible alarm built into the control panel alerts the dock attendant to potentially unsafe conditions, such as broken or missing ICC bars

- Audible touch buttons and keypad provide instant sound feedback to user input

RECOMMENDED APPLICATIONS

- High-volume cargo handling applications

- Locations that frequently experience wet or flooded conditions

AVAILABLE OPTIONS

- Pit-mounted hydraulic powerpack

- Extension plates

- Zinc finish or hot-dipped galvanizing for extension plates

- Weather seal kit